LED display manufacturer HTL has always been at the forefront of the industry with its strong spot production capacity and highly cost-effective price advantage! Hôm nay, we will summarize the differences between DIP LED display screens and surface mount LED display screens, which are commonly asked by customers

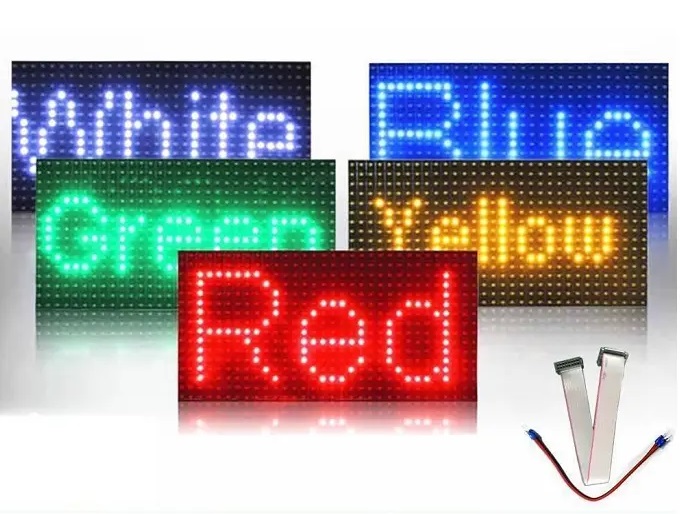

The packaging of direct insertion LED adopts the form of encapsulation. The process of encapsulation is to first inject liquid epoxy resin into the LED molding cavity, then insert the LED bracket that has been pressure welded, and place it in an oven for the epoxy resin to cure. After that, the LED is detached from the mold cavity and molded. Due to its relatively simple manufacturing process and low cost, it has a high market share. The direct insertion type has a large volume and can be operated by manual plug-ins or AI machines. Due to the high brightness of the direct insertion LED and the ease of waterproof treatment, it is generally used as a light source for outdoor LED displays.

SMT LED is attached to the surface of the circuit board, suitable for SMT processing, and can be reflow soldered. It effectively solves the problems of brightness, góc nhìn, bằng phẳng, độ tin cậy, consistency, Vân vân. It uses lighter PCB boards and reflective layer materials. After improvement, the heavier carbon steel material pins of the direct insertion LED are removed, so that the display reflective layer needs to be filled with less epoxy resin, aiming to reduce size and weight. Theo cách này, surface mount LEDs can easily reduce the weight of the product by half, ultimately making the application more perfect. SMT LED is generally used as the light source for indoor LED screens, but with technological breakthroughs, the brightness of SMT LED has been greatly improved, and waterproof treatment can also be well solved. vì thế, SMT LED is increasingly being applied to outdoor LED displays.

Trong những năm gần đây, due to the continuous improvement of production processes and technologies, outdoor surface mounted LED displays have gained great development space. Compared to direct insertion display screens, outdoor surface mount display screens are glue free, thinner and easier to install. Combining its own advantages, it is more suitable for rental companies, vehicle mounted screens, and mobile media use. Column installation or wall installation reduces the pressure of the screen on the steel structure. Ngoài ra, surface mounted full-color LED displays have a large visual appeal, good light distribution and color mixing effects, delicate images, and moderate brightness, making them suitable for large-scale automated production. Tuy nhiên, the efficiency and attenuation speed are relatively high, and the adaptability to harsh environments is relatively poor. Tuy nhiên, surface stickers have unique characteristics and advantages that cannot be surpassed by direct insertion displays in terms of color reproduction, color consistency, đồng nhất, góc nhìn, and overall picture effect.

Although the direct insertion LED full-color display screen has good sealing, Độ sáng cao, strong environmental adaptability, and is suitable for long-distance viewing, it has an absolute competitive advantage. But the perspective is slightly smaller, the color uniformity is slightly worse, and the production process is slightly more complex. In the field of outdoor ultra large screens, surface mounted LED displays are somewhat inadequate compared to direct insertion screens in terms of cost and display brightness. Ngoài ra, with the sensory effect of visual distance, it costs a lot to replace the direct insertion screen with a surface mounted screen, which is like losing sesame seeds and picking watermelon. vì thế, considering the special usage environment and the advantages in cost and brightness, there is still a great market demand for direct insertion screens.